When it comes to towing a trailer, ensuring your trailer lights are properly hooked up is crucial for safety on the road. In this blog post, we will walk you through the process of hooking up trailer lights and provide you with tips to ensure the connection is secure and tricks to troubleshoot a faulty connections, making the task easier.

We will also walk you through the different types of trailer wiring harnesses, explain how they work with different types of trailers and even break down wire colors and their purposes. While there is some overlap with our rewiring trailer lights blog the focus here is on the essential steps to connecting your trailer lights correctly.

So, dive in and we’ll guide you on how to hook up your trailer lights like a pro!

First, Make Sure You Have All the Essential Parts Needed for a Working Trailer Light System

To ensure your trailer lights function properly, there are a few essential components you need. First, your vehicle needs a standard connector that matches your trailer’s connector. Without a matching connector the vehicle harness and trailer lights will not be compatible.

This means your vehicle will need a wiring harness with a matching connector for your trailer and your trailer will also need a harness, tail lights and light bulbs, if it doesn’t have a wiring setup already.

If your vehicle doesn’t have a matching connector, you can explore CURT’s line-up of custom wiring and T-connectors for a solution. Similarly, your trailer should have a compatible connector and CURT Manufacturing offers electrical adapters for various towing electrical needs.

Lastly, you will need to make sure your trailer has a working electrical system before towing, which includes functional trailer lights. If any of these components are faulty it can cause issues with your trailer lights. To browse trailer tow lights and lamps, view the comprehensive CURT selection of trailer and tow Lights.

Understanding the Differing Types of Trailer Connectors: From Common 4-Way Flat Connectors to 7-Way Connectors

Before towing, you will need to know about the variety of connector types that are commonly used for towing different types of trailers, with the 4-way flat connector being the most common for towing utility trailers and the 7-way connectors being the most common for towing RVs and 5th wheel travel trailers.

It is important to understand the types of connectors that are available to ensure you have the correct wiring system for the type of towing you plan to do. Towing with the correct wiring setup ensures a safe, reliable tow. Likewise, you need to identify the different connector types to ensure your trailer and tow vehicle have compatible wiring systems before you tow, as there are different options for each type of towing scenerio.

Here’s a brief overview of common connector types and each of their uses:

4-Way Flat Connector:

The 4-way flat connector is the most basic and commonly found connector type. It features a flat- style connector that consists of four pins or terminals that correspond to the basic lighting functions: left turn signal, right turn signal, brake lights and running lights.

This type of connector is typically used for small utility trailers, pop-up campers and boat trailers.

5-Way Flat Connector:

The 5-way connector features a flat- style connection, similar to the 4-way flat connector, but includes an additional pin for auxiliary power or reverse lights. This type of connector is often used for trailers that require an extra power source, such as trailers with hydraulic brakes or those equipped with backup lights.

6-Way Flat Connector:

The 6-way connector features a circular style plug and is commonly used for trailers that require additional functions beyond the basic lighting. In addition to the four pins found in the 4-way flat connector, the 6-way connector includes two additional pins for electric brakes and battery charging.

This type of connector is often used for larger trailers, including enclosed trailers, RVs and horse trailers.

7-Way Connectors:

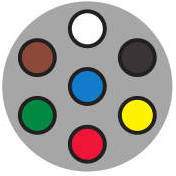

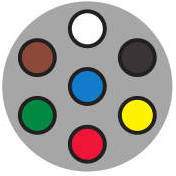

The 7-way connector, similar to the 6-way connector, also features a circular-style plug and is the most versatile and comprehensive connector type.

It includes all the functions of the 6-way connector with the addition of a separate pin for a dedicated ground connection. 7-way connectors are commonly used for large RVs, fifth-wheel trailers, heavy-equipment trailers and livestock trailers.

It is important to note that there are two types of 7-way connectors: the 7-way pin connector and the 7-way blade connector, which are typically used with different types of trailers.

7-Way Round Pin Connector:

The 7-way pin connector, also known as the RV-style connector, features round pins housed in a circular socket. It is commonly used in recreational vehicles (RVs), campers, and some larger trailers. The 7-way pin connector provides connections for all the various functions needed for towing large RV trailers and 5th wheel campers.

Traditional 7-Way Blade Connector:

The traditional 7-way blade connector, also referred to as the 7-way RV blade connector or flat blade connector, has flat metal blades enclosed within a rectangular housing. It is commonly used when towing modern 5th wheel trailers, travel trailers and campers.

The 7-way blade connector uses a similar wiring harness as the 7-way pin connector, however, instead of pins, it simply has blades in place, which provide for a more secure connection.

It is important to note that the traditional 7-way blade connector is distinctly different from the SAE J2863 7-way blade configuration, which is commonly used with gooseneck trailers, utility trailers, equipment trailers and cargo trailers.

In order to tow successfully, the connector type on your vehicle must match the connector type on your trailer for a compatible connection. However, if your vehicle and trailer have different connector types, adapters are available to bridge the gap and ensure compatibility.

Understanding the specific connector type on your trailer will help you identify the correct wiring configuration and ensure that all lighting functions work properly when towing.

For other connector types, such as 4-way round or 6-way square connectors, see Towing 101: Trailer Wiring with Diagrams.

Pro Tips for Hooking Up Trailer Lights to Ensure a Reliable Connection & How to Troubleshoot Issues

Now that you have a good understanding of the different types of wiring harnesses and connector types and have the lights, wiring harness and compatible connectors you need to tow, you’re ready to hook up and go.

Hooking up trailer lights involves more than just plugging in connectors. You’ll want to make sure your connection is reliable before setting out onto the road.

Ensuring the connection is reliable will ensure you are safe when on the road, prevent the need to stop and troubleshoot and even help you to avoid accidents and tickets.

To ensure your connection is reliable, follow these pro tips in this step-by-step guide to ensure a successful connection and a safe, reliable towing experience.

Tip #1 – Ensure Connectors Match Before Planning to Tow:

Before attempting to connect your trailer lights, make sure the harness on your vehicle and trailer match to avoid a situation where the trailer and tow vehicle are different. As mentioned earlier, there are different connector types, so in the case that the connecgors are different, using adapters can help bridge the gap between different connector types. If you do not double check the connector types, you may end up in a crunch where you need to tow and suddenly realize that your wiring harness and trailer aren’t compatible. If this is the case, shop CURT adapters for a quick solution.

Tip #2 – Ensure Connectors are Firmly Pressed Together:

Once you have identified the matching connectors, firmly press them together. This ensures a secure electrical connection and helps maintain uninterrupted power flow between the vehicle and trailer. Be sure that the male connector is pressed fully into the female connector. The base of the male connector should be seated against the base of the female connector. This ensures that they’re fully connected. If they are not fully connected, some lights and functions may not work as intended.

Tip #3 – Secure the Connection to Prevent Harness Damage when Towing:

It’s essential to safeguard your trailer harness from potential damage during travel. Take precautions to avoid situations where the harness could be pinched, dragged on the ground, severed, or twisted up with the chains. To do this, make sure that the wiring harness does not have too much or too little slack. If the harness has too little slack, it can cause stress to the wiring when turning. Additionally, ensure that the harness has enough slack to allow for turns without dragging or getting caught.

Tip #4 – Conduct a Light Function Test Before Towing:

Before hitting the road, it’s crucial to test your trailer lights to ensure they are functioning correctly. Enlist the help of a friend to watch and test each light’s function one at a time. This includes checking the left turn signal, right turn signal, brakes and running lights. Confirm that all lights illuminate as intended so that once you are on the road, traffic and other vehicles are aware of you as you drive, and you can signal to them when braking or changing lanes.

Tip #5: Disconnect and Reconnect If Something Doesn’t Work:

If any of the light functions are not working properly, simply double check the connectors to ensure they are securely connected. Sometimes, a loose connection can cause issues with the lighting system. If you do have issues, simply disconnect and reconnect the connectors and then retest. And, on older vehicles and harness connections, using a die-electric grease can help conductivity. If issues persist, check the fuse(s) on the wiring harness and also check the wiring harness on the vehicle and trailer for cut, corroded or damaged wires. If using a taillight converter, you can also check to make sure your taillights are working properly and double check the connection to the taillights.

Tip #6: If Issues Persist, Don’t Forget to Check Lightbulbs:

Sometimes, if the trailer lights aren’t working properly the problem might be as simple as a burnt-out or damaged lightbulb. Take the time to check all the lightbulbs on your trailer and replace any faulty ones promptly before going into deeper troubleshooting of the tow harness.

Tip #7: Visually Inspect and Troubleshoot Trailer Wiring and Lamps:

If lighting issues persis, visually inspect the wiring starting at the trailer tongue and working your way back to the rear lamps. Look for any signs of damage, corrosion or wear and use a wire tester to check the integrity of the wiring. CURT Manufacturing offers various electrical testers that are specifically designed for towing applications and help to quickly troubleshoot sockets and wiring harnesses.

Tip #8: Check the Power, Ground and Fuses if Still Having Issues:

A common cause of wiring issues is a corroded or loose power or ground connection. Ensure that the ground connection between the trailer and the vehicle is secure and clean. A solid power and ground connection is crucial for the proper functioning of the trailer lights. See the diagrams below to understand which color wires are the power and ground wires for your specific towing setup.

Tip #9: Use an Electrical Tester to Verify Vehicle Socket Functionality:

If issues persist, check the vehicle socket to ensure the electrical signal is functioning correctly at the tow vehicle socket. If all connectors are secure but the lights still don’t work, use an electrical tester to ensure that your vehicle’s socket is functioning correctly. CURT offers socket connector testers that are specifically designed for towing applications and help to quickly troubleshoot sockets and wiring harnesses.

Tip #10: Replace Damaged Components:

If you identify any damaged components during the inspection, such as frayed wiring or broken connectors, replace them before towing your trailer. Using damaged components can lead to unreliable lighting and potential safety hazards.

Finally, Make Sure You Properly Cover Connectoins when Not in Use:

When not in use, it’s important to keep the connectors (both on the vehicle side and trailer side) covered with caps to protect them from dirt, moisture and corrosion. Additionally, store the trailer harness safely in your trunk or a designated storage compartment to prevent damage and tangles.

By following these comprehensive tips, you can ensure a secure and functional connection for your trailer lights, enhancing your safety while towing and complying with legal requirements.