The fleet of five Airbus-operated BelugaSTs has been operating since the mid-nineties to meet the European airframer’s requirements for inter-site transportation of large aircraft sections.

The arrival of a BelugaST ‘Super-Transporter’ at Chennai Airport recently marked a rare appearance of the outsize transport aircraft over Indian skies. This was also the first occasion of a BelugaST landing at Chennai Airport. The aircraft — Beluga No.2 refuelled at the airport before it continued on its onward journey. Announcing the arrival of the giant transporter at Chennai Airport, ‘The cargo transporter is a rare visitor in this part of the world,’ the Airports Authority of India (AAI) said in a tweet.

The BelugaST is the short name given to the A300-600ST ‘Super Transporter’, a unique aircraft developed by Airbus to transport outsized cargo. These A300-600ST aircraft were based on Airbus’ legacy A300 jetliner and given the ‘Beluga’ moniker due to their resemblance to Beluga — white whale. The fleet of five Airbus-operated BelugaSTs has been operating since the mid-nineties to meet the European airframer’s requirements for inter-site transportation of large aircraft sections. However, the aircraft are being replaced by six new-generation BelugaXLs, which are based on the newer and more modern A330-200 aircraft. All six BelugaXLs are slated to be fully operational by 2023.

Outsize Freighter

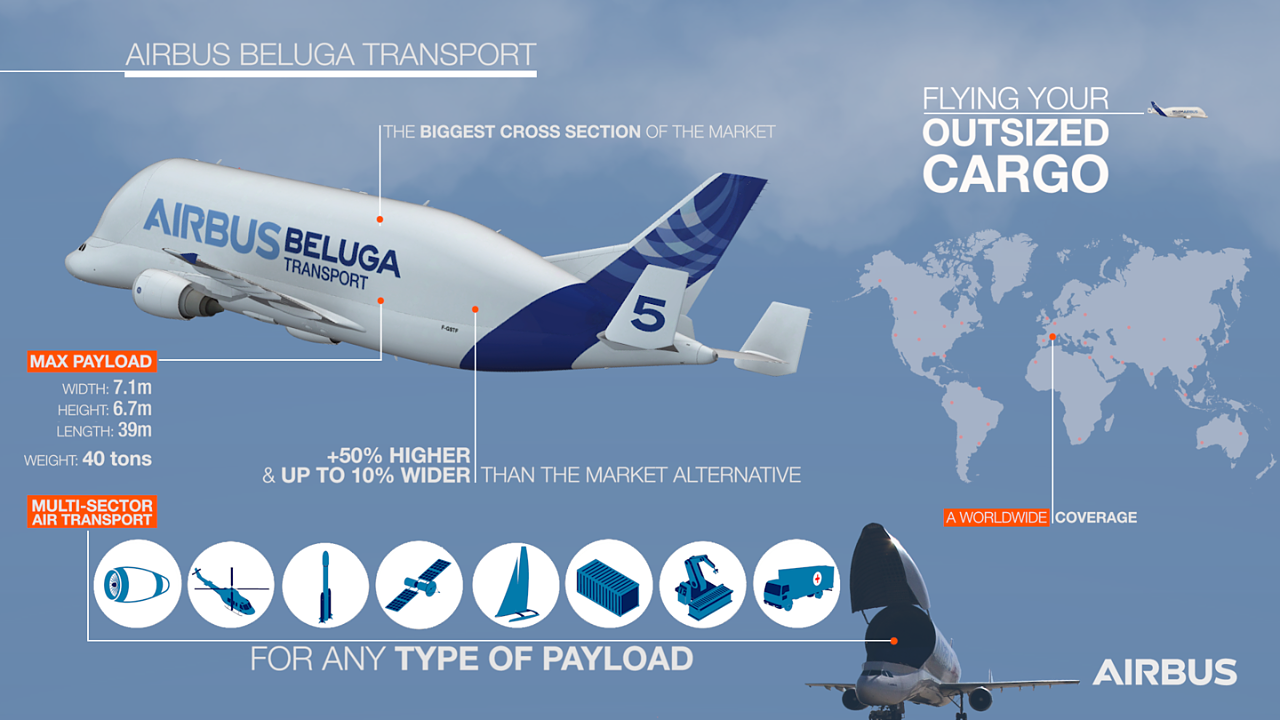

In January this year, Airbus announced that its BelugaST fleet would transition away from ‘in-house’ duties and be available for outsized freight transportation for customers worldwide. Offered as part of the Airbus Beluga Transport commercial service, the five A300-600ST aircraft will exclusively provide large cargo transport solutions for customers in a variety of sectors, including engine manufacturers; space industries; helicopter manufacturers; oil & gas and energy providers; machinery manufacturers; land vehicles and other military equipment; humanitarian supply distributors, to name a few.

According to Airbus, the BelugaST airframes still have plenty of available flight-hours remaining before reaching their original design service limits and hence can operate for many more years. The fifth and final BelugaST aircraft was inducted into service in 2001, and the five aircraft fleet has completed more than 10,000 total flight hours.

Airbus launched the new service dedicated to ‘outsized freight’ customers in the last week of December 2021. This involved transporting a new helicopter from Airbus Helicopters’ manufacturing site in Marignane, France, to Kobe in Japan on BelugaST No 3. Its wider cross-section allows transportation of helicopters without having to dismantle them first, which is a major advantage for Airbus.

The initial flights with the BelugaST are being operated by Airbus’ in-house ‘airline’ Air Transport International (ATI), using its own aircrew. However, a newly created dedicated subsidiary airline with its own Air Operator Certificate (AOC) and staff is being planned to operate these aircraft. This will occur after Airbus has commissioned all six new BelugaXLs into service. Airbus will also upgrade the BelugaSTs with a new-generation Flight Management System with ADS-B for enhanced intercontinental navigational capabilities.

Some of the other commercial customers for transport of outsized freight would also include satellite manufacturers, many of whom are today constrained by the availability of transport means. The BelugaST will allow transportation of larger satellites. Airline customers will also benefit from access to the BelugaST as it is the only aircraft which can transport an aircraft engine and inlet in a fully dressed configuration. On other smaller transport aircraft available presently, these engines would first need to be partially dismantled and then reassembled and re-tested, which would take around two days. The ability to transport a complete engine will allow airlines to quickly resolve Aircraft on Ground (AOG) situations when a new engine is required.

Airbus is also developing new loading techniques and equipment to maximise the BelugaST’s short turnaround capability. The aircraft feature a semi-automated main deck cargo loading system and an automated On-Board Cargo Loader (OBCL), which became available in 2022. The automated OBCL can cater for payloads weighing up to 20 tonne and will allow the aircraft to operate from/to airports which do not have suitable loading/unloading platforms. The OBCL is transported inside the aircraft and is stored in front of the internal payload hold area. Airbus has also developed and deployed a new Multi-Purpose-Pallet (MPP) for the BelugaST, which is compatible with a range of payloads.

The BelugaST A300-600ST is derived from the company’s shorter-fuselage A300 and features the same flight deck as legacy Airbus A300-600s and A310s. Its cockpit controls can also operate a transportable heating module that can be installed in the main deck cargo compartment. This allows for temperature-controlled conditions to transport sensitive payloads such as satellites.

The BelugaST has the largest interior cross-section of any transport aircraft in the world, with the ability to accommodate cargo of up to 7.1m in width by 6.7m in height. It can carry a maximum payload of 40 tonne. The aircraft has a Maximum Take-Off Weight (MTOW) of 155 tonne and can carry up to 24,000 litres of aviation fuel.

BelugaXL Takes Up The Mantle

The BelugaXL programme was launched in November 2014 and essentially comprised the forward section of an A330-200F freighter with the aft section of an A330-300. It will carry larger sections of Airbus aircraft, including a full wing-set for the A350-1000, between Airbus’ European production sites and to final assembly lines in Toulouse (France) and Hamburg (Germany). The six aircraft will provide 30% additional transport capacity for Airbus’ industrial network.

Compared to the BelugaST, the BelugaXL has an enlarged fuselage “bubble” section that is 6m longer and 1m wider. The main physical differences between the BelugaST and XL versions are the incorporation of a new dorsal fin that connects to the vertical tailplane and the addition of new ventral fins, which both have the same stabilising function.

The dorsal fin on the larger BelugaXL was increased in size and produced in three parts with a distinctive ‘kink’ in the diagonal. On the Beluga ST, this triangular component is produced as a single part. An updated horizontal tailplane was also incorporated to cater for the need for greater stability.

The BelugaXL’s cockpit has been lowered to make space for the main deck and allows for direct loading/unloading of cargo. Airbus has used the same nose landing gear as on the A330 to reduce development and maintenance costs. This has also resulted in a lower cockpit position than on the BelugaST. The addition of a large ‘bubble’ airframe section to the A330s lower fuselage increases its diameter to 8.8m as compared to the 5.6m on the A330. These changes were made to achieve Airbus’ requirement for a 50-tonne payload capability and a 45m long cargo hold to be with an internal diameter of 8m.